ThOR 10

ThOR 10

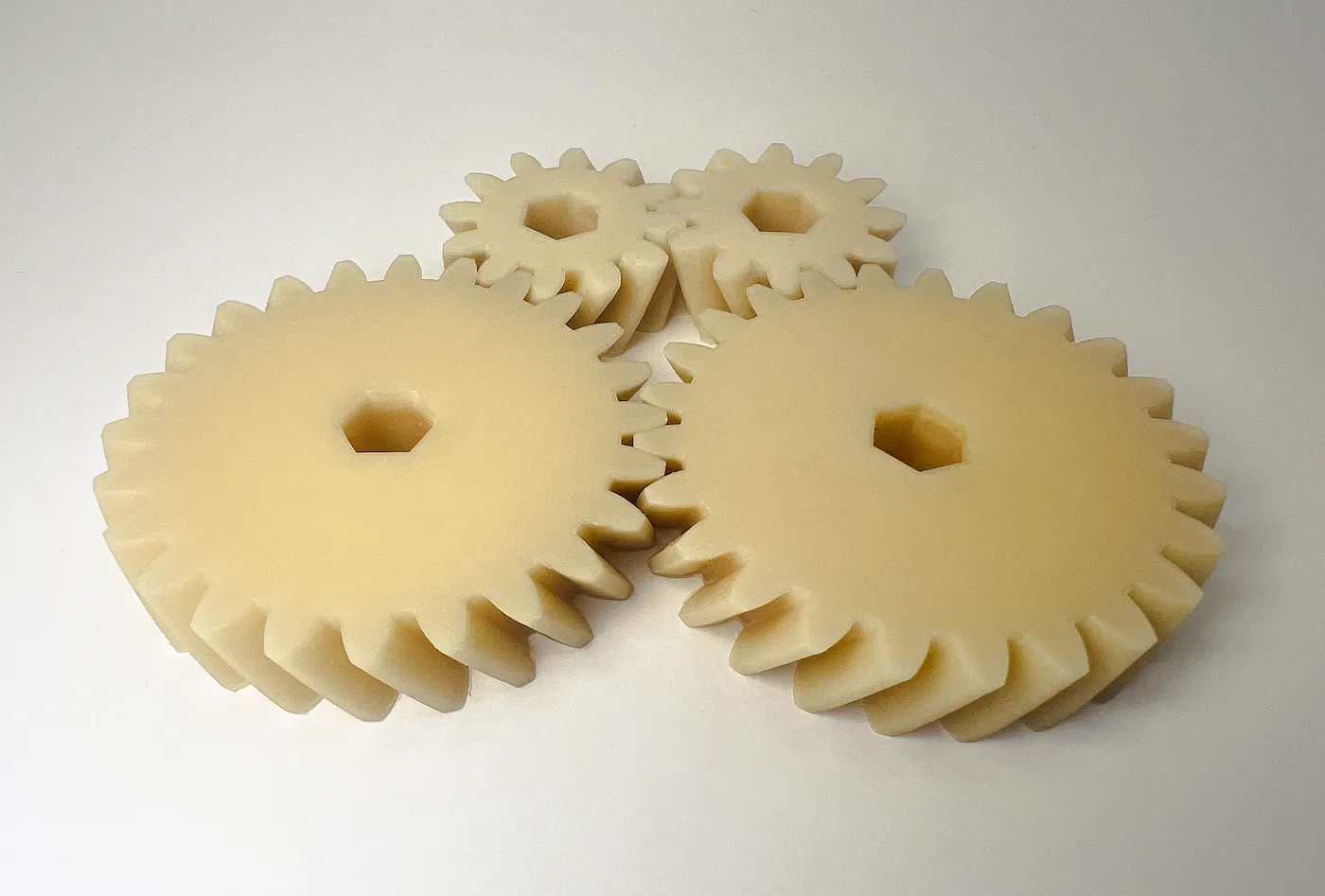

ThOR 10: A rugged, ceramic-filled composite photopolymer combining impact resistance, thermal stability, and chemical resistance for demanding industrial applications.

Why ThOR 10?

Ceramic-Filled Performance for End-Use Additive Manufacturing

ThOR 10 combines Tethon 3D’s high-performance ceramic fillers with polySpectra’s rugged Cyclic Olefin Resin, unlocking new possibilities for production additive manufacturing in demanding applications like aerospace, automotive, defense, and electronics.

High Impact Strength

Achieves substantial toughness with a Notched Izod impact strength of 55 J/m and >20% elongation, allowing parts to absorb energy without fracturing easily.

Excellent Thermal Stability

Durability is maintained at elevated operating temperatures thanks to a high Glass Transition Temperature (Tg) of 131°C (268 °F).

Stiff & Chemically Resistant

Offers high stiffness (2.0 GPa Tensile Modulus) and the inherent chemical resistance of Cyclic Olefin Resins, suitable for fluidic manifolds and harsh environments.

Take Your Onsite Additive Manufacturing to the Next Level with ThOR 10

COR photopolymer resins are intended for use by trained additive manufacturing professionals working in industrial, manufacturing, and laboratory facilities. At this time, we discourage printing with COR in home or office environments.

Please review the documentation before ordering resin.

Read the DocsPlease review the documentation before ordering resin.

Not Ready for Resin?

Don’t have the right equipment? No problem.

polySpectra can print ThOR 10 parts for you. Simply drag and drop your CAD or 3D model file for an instant quote.

Get an Instant QuotepolySpectra can print ThOR 10 parts for you. Simply drag and drop your CAD or 3D model file for an instant quote.

Rugged resin you can trust.

The core is COR. Now ceramic-filled.

ThOR 10 incorporates Tethon 3D’s advanced ceramic filler into polySpectra’s COR material family. Key features include:

- Exceptional Impact Strength

- High Thermal Stability

- Excellent Stiffness

- Inherent Chemical Resistance