CNC encompasses a range of tooling processes to ensure repeatability and accuracy on a large scale. 3D printers are also apt at incredible accuracy, but specifically for small scale parts. This article compares CNC vs 3D printing. Continue reading to learn how 3D printing retains the design flexibility of CNC with the small scale repeatability of injection molding.

What is CNC?

CNC, or computer numerical control, is a process invented in the 1940s and 1950s as a means to ensure precision using existing tooling in mass manufacturing. CNC encompasses a range of tooling including lathes, plasma cutters, and mills. CNC is applied to many materials, including metals, woods, and polymers. As such, CNC and 3D printing compete in some manufacturing spaces.

Using CNC vs 3D printers

Why use CNC?

Not unlike 3D printing, CNC ensures accuracy across mass produced parts in manufacturing. CNC is generally applied to large scale parts. One major example of CNC is in the aerospace industry: airplane parts require a great deal of precision, engineered for aerodynamics, structural integrity, and ultimately, safety.

Why use 3D printers?

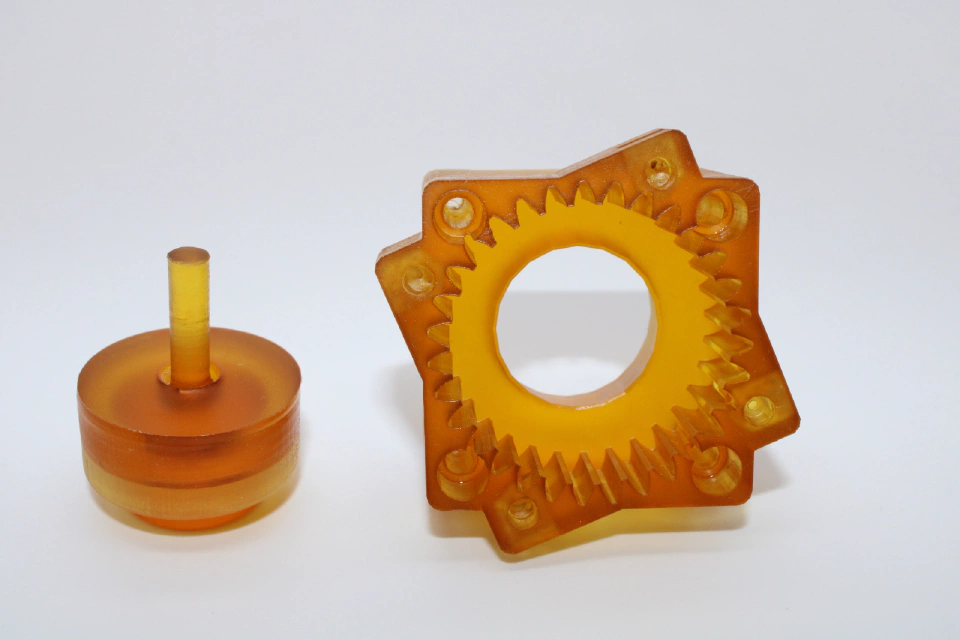

3D printers are apt at incredible accuracy with small scale parts. A great example are electrical connectors which like airplane parts, require a great deal of accuracy to work as designed. Given their small scale, however, CNC is not practical. Generally, electrical connectors are manufactured via injection molding. However, using digital light processing in 3D printing, we are able to manufacture electrical connectors with great precision and design flexibility that injection molding cannot offer.

3D printing offers you the flexibility to manufacture with precision on a smaller scale vs CNC (such as the option to include serial numbers on your parts). 3D printing is a great alternative to injection molding for small scale parts because it offers greater design flexibility, such as latticework interior for lightweight parts. Additionally, components that require several CNC parts to build can be assembled as a single 3D printed part. Furthermore, the process of 3D printing generally produces less waste material than CNC.

Learn more: Injection Molding vs 3D Printing

Convert CNC to 3D Printer Use

3D printing offers the design flexibility of CNC with the small scale repeatability of injection molding. There are many advantages to using 3D printing vs CNC. If you have a part designed for CNC that you want produced on a small scale, polySpectra is here to help. Apply to work with our design team to source alternative materials and adjust your design for 3D printing.