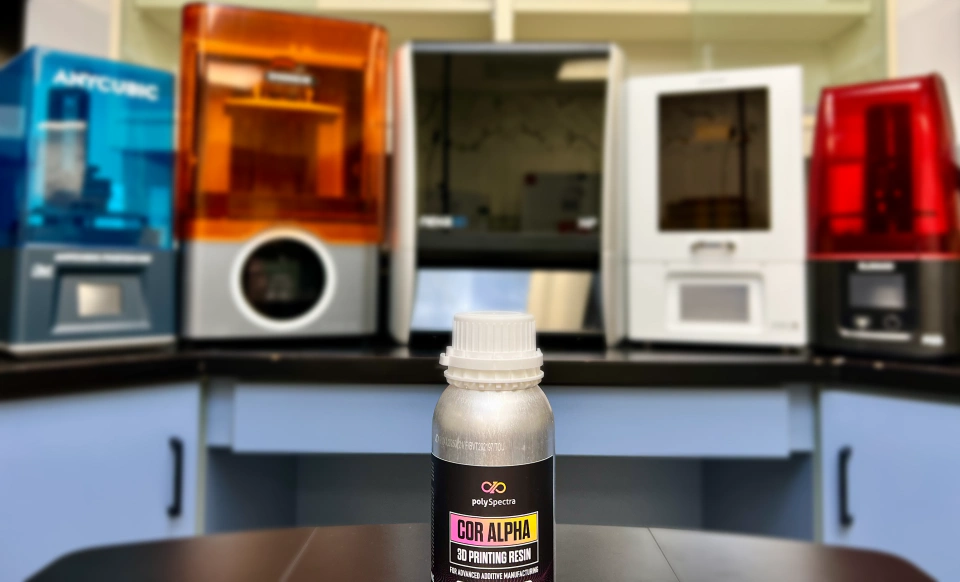

Ultra-rugged photopolymer 3D printing moves to the desktop with all-new 405nm-compatible resin offering.

Today we are very excited to announce the launch of our flagship material in a new formulation compatible with desktop DLP and LCD resin 3D printers. Previously available solely for use on 385nm wavelength 3D printers, limiting use to industrial hardware, the new formulation expands availability to 405nm wavelength systems.

“We founded polySpectra with a mission to democratize manufacturing. Today, we are very excited to announce the 405nm version of COR Alpha – which now gives engineers the ability to access the world’s most rugged photopolymers on a wide array of resin 3D printers spanning every price point,” said polySpectra Founder and CEO Raymond Weitekamp, PhD.

Real End-Use 3D Printing

While many “production-grade” resins available today for 3D printing can create high-resolution parts with unique geometric complexity, they are often too brittle for demanding real-world applications. This inherently limits their use to prototyping and other less-demanding use cases.

COR stands for “Cyclic Olefin Resin,” a new family of engineering-grade materials for additive manufacturing developed by polySpectra. COR Alpha relies on Nobel-winning chemistry to offer durability, high impact strength, high-temperature performance, and moisture- and chemical-resistant capabilities – all without brittleness. Satellite components, consumer products, electronics connectors, and highly durable tooling for injection molding are just a few of the high-value applications where COR Alpha can tip the scale from prototyping to production.

COR Alpha has been commercially available since 2022 in a 385nm wavelength, compatible with and validated on a catalog of industrial-grade 3D printers.

Democratizing Production-Grade Additive Manufacturing

This ruggedness is now more accessible than ever before. The new COR Alpha resin 405nm formulation dramatically expands the list of compatible 3D printers. For the first time, inexpensive desktop 3D printers will have the capability to print with truly rugged resin.

R&D labs, small businesses without industrial budgets, and other users – many who already own desktop 3D printers – now gain the ability to create end-use parts in-house.

“The only difference between a toy and a tool is what it can produce,” Weitekamp said. “Whether you are running a $250 LCD printer or a $250,000 DLP machine – COR Alpha unlocks a step-change in ROI.”

As of launch, 405nm COR Alpha is fully validated for use on Asiga 3D printers. Additionally, many of the best-selling desktop 3D printer models out there are on the list of polySpectra’s exploratory 3D printers, including systems from Anycubic, Elegoo, Nexa3D, Phrozen, and Shining3D.

Over the next few weeks, polySpectra will announce validated print profiles for COR Alpha for many specific 3D printer models, in collaboration with these hardware manufacturers and others.

Equipment requirements and print profiles are available here. 405nm COR Alpha is immediately available for order at shop.polyspectra.com

Contact

Partnerships

Rakesh Jain - COO & Head of Partnerships

partners [at] polyspectra [dot] com

Media Inquiries

Sarah Goehrke - Additive Integrity for polySpectra